The innovative online business project MyWay is excited to share the success of its livestream interview series, connecting students of the University of Applied Science Kufstein Tyrol with illustrious alumni. This initiative, focusing on the Sport, Culture, and Event Management (SCEM) Master’s Degree program, has significantly bridged the gap between current students and successful professionals in the industry.

Makers Lab

Implement your own ideas and hold the result in your hands immediately: This is the motto of the Makers Lab, available to both students and staff of at the University of Applied Sciences Kufstein Tirol.

The laboratory equipment allows users to

- test concepts and

- manufacture everything from prototypes to final products and small batches.

In other words, all essential steps in the creation of a product can be performed here.

Our partners

Support from our corporate partners allows us to make available state-of-the-art equipment in the Makers Lab.

Concept development

PC workstations with various CAD programs and a range of programming environments are available for concept development.

Example

In the course Interaction Design & Product Design of the master’s program Smart Products & Solutions, a Data Explorer was developed together with our external lecturer Mara Lindner.

Concept and implementation: Franz Hubauer, Alexander Führen, Markus Ehrlenbach.

The steps from the idea to sketches, a CAD model, and the finished project:

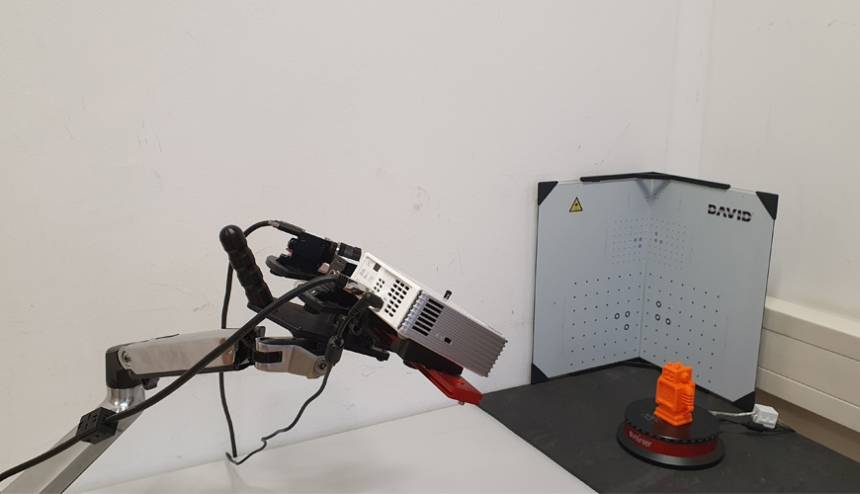

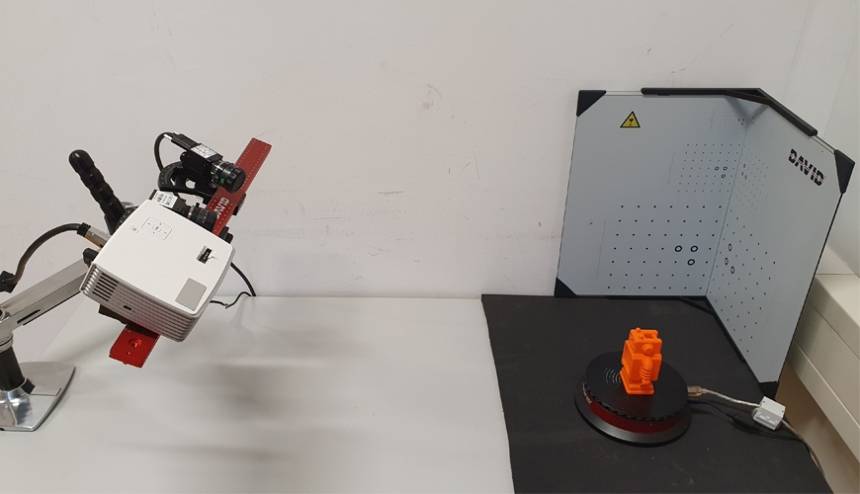

Digitizing real-life objects

Real-life objects can be digitized with the help of 3D scanners.

3D-Scanner

3D-Scanner

Rapid prototyping

Rapid prototyping is the rapid production of samples, models, and prototypes from digital drawings (2D or 3D CAD drawings).

Rapid prototyping can be extended to include the terms rapid tooling and rapid manufacturing.

- The aim of rapid tooling is the fast production of tools and tool molds.

- Rapid manufacturing is the rapid production of final products. When looking at production time in this approach, not only pure production time is taken into account, but also the development and construction of the production facilities.

The manufacturing processes used in our Makers Lab are additive manufacturing, also known as 3D printing, and material processing using a laser engraving machine.

Additive manufacturing

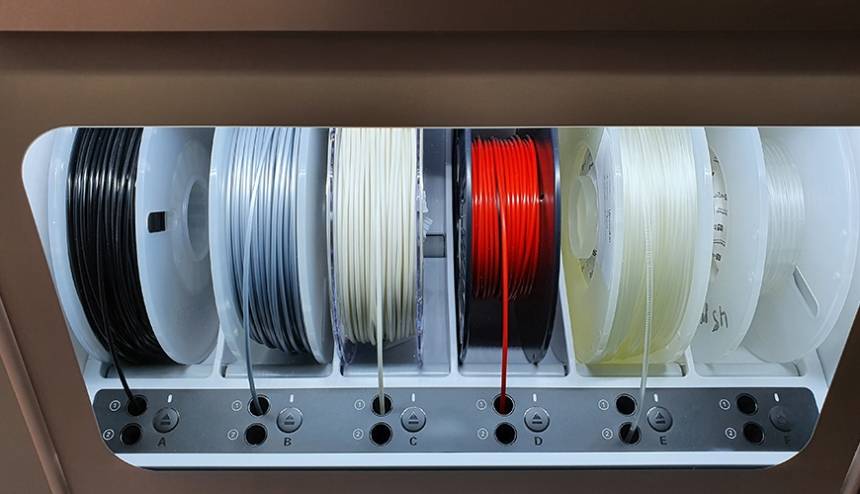

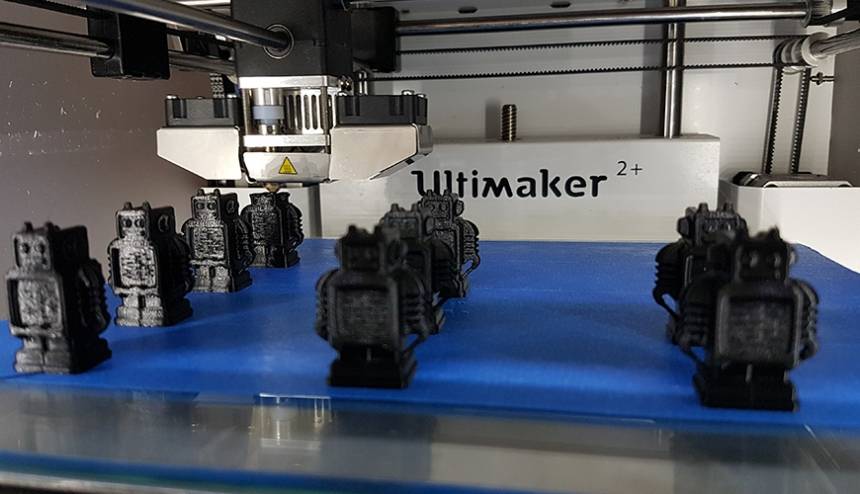

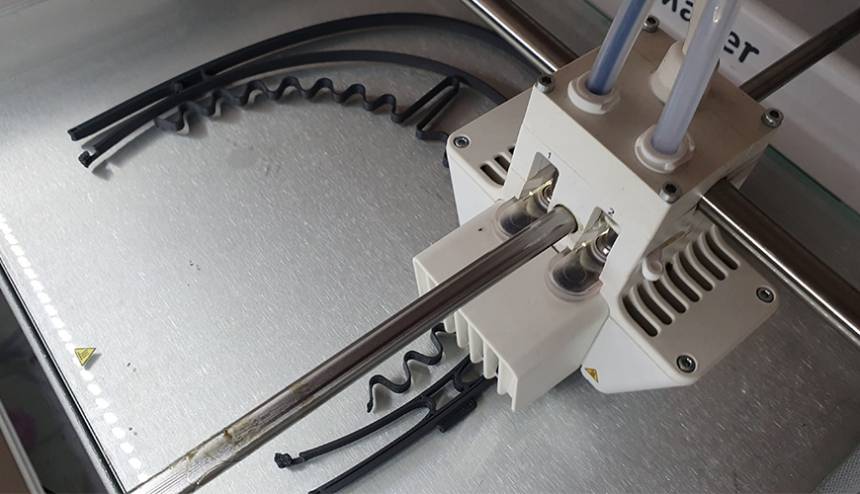

To realize the digital concepts, there are a number of 3D printers to choose from that operate on different principles, such as material extrusion (MEX, FFF, FDM) and stereolithography (DLP).

3D printer Ultimaker S5 Pro Bundle in the Makers Lab I

Materials station of the 3D printer Ultimakers S5

Robot as a small gift item, manufactured using the 3D printer Ultimaker 2

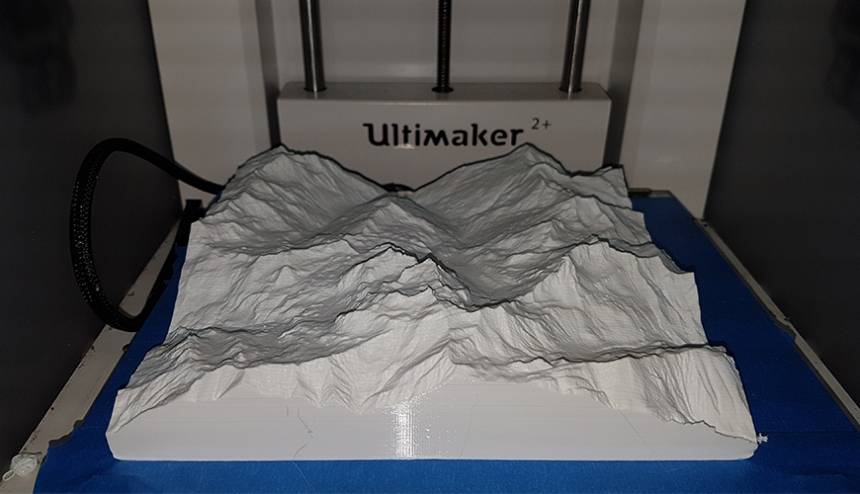

Wattener Lizum mountain range for an avalanche course

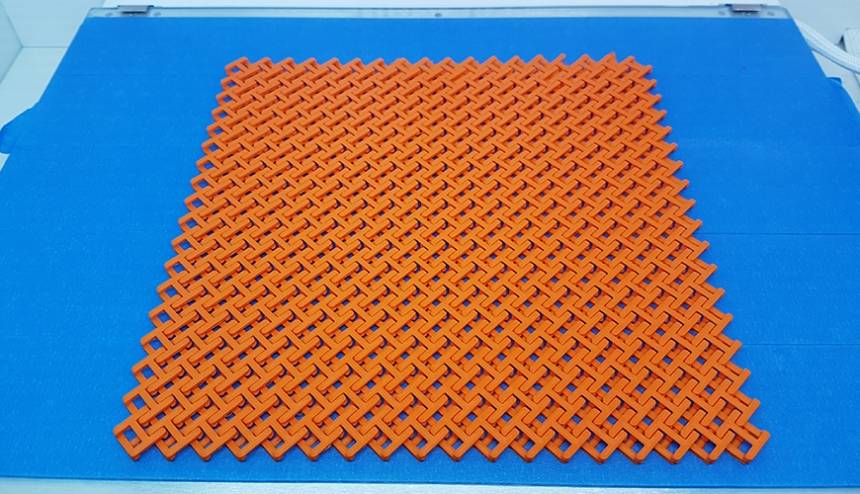

Print-in-place 3D printed and linked elements as a flexible fabric

Print-in-place 3D printed cogwheels

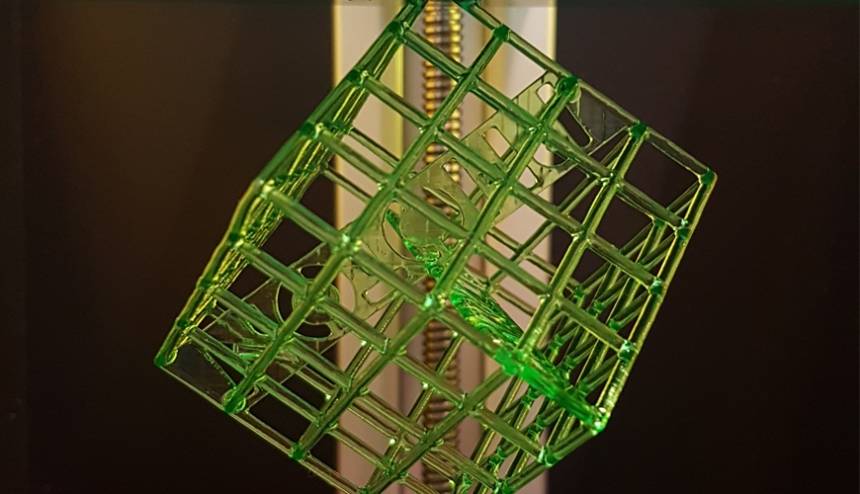

Delicate cube, manufactured through DLP (stereolithography)

Funnel (Shops were closed, so it was simply 3D printed on site for personal use.)

3D printed differential gear

Retaining straps for face mask, made from TPU material

Face shield with a production time of less than an hour

Laser cutting and engraving

In addition to 3D printing, laser cutting with our laser engraving machine (CO2 laser) is particularly useful for quickly realizing concepts.

Laser engraving machine Trotec Speedy 100 in the Makers Lab I

Laser engraving machine Trotec Speedy 100 in the Makers Lab I

Planetary gear made of wood, cut out with a laser cutter

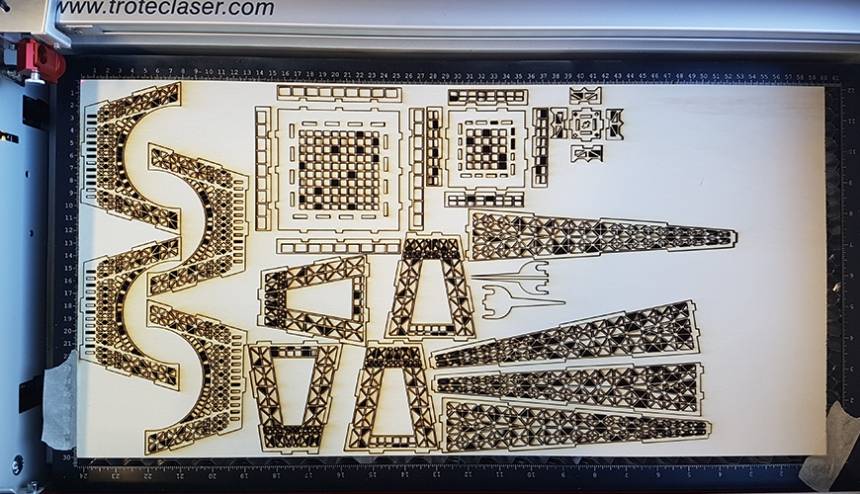

Individual parts for a model of the Eiffel Tower, cut out with a laser cutter

Wall clock made of plywood and labeled plastic (cogwheel themed)

Engraved acrylic sign for the project Smart Factories – Connected Learning. Self-developed LED base including circuit board and engraved sign.

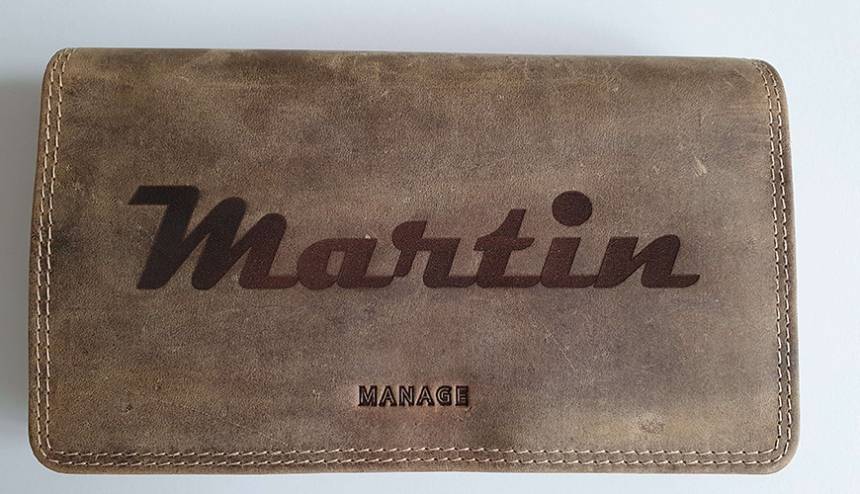

Leather wallet inscribed with laser engraving machine.

Wall clock made of plywood and acrylic (mountaineering themed)

Cutting of elements for a wall bracket; bracket for curtain rods on a wall.

Additional equipment

The following tools (and a wealth of others) are available for implementing one’s own ideas.

- Circuit board printer

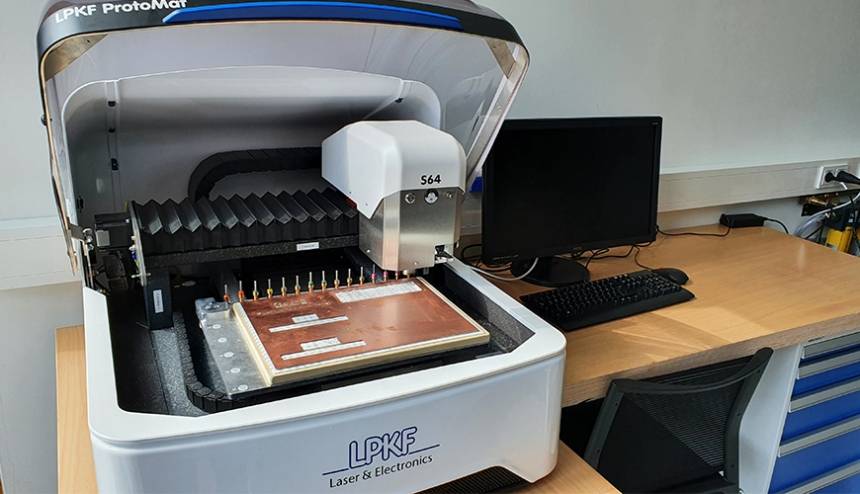

- PCB milling machine

- Climate test chamber

- Soldering stations

- Measuring devices and gauges

Climate test chamber and workbenches in Makers Lab 2

Experimental setup in the climate test chamber with 3D printer

LPKF circuit board milling machine in Makers Lab 2

Laboratory license

To qualify for use the Makers Lab, a laboratory license and subsequent training on the equipment is offered.

Navigation

News of the FH Kufstein

Der erste erfolgreiche Gesundheitstag am 18. April an der FH Kufstein Tirol verlief mit Energie und Enthusiasmus. Dabei erlebten Mitarbeitende, Studierende und die Öffentlichkeit ein kostenloses und vielseitiges Programm, das Gesundheit und Wohlbefinden in den Mittelpunkt stellte.

In einer Reihe von herausragenden Praxisprojekten haben sich Studierende des Masterstudiengangs Smart Products & Solutions an der FH Kufstein Tirol mit zukunftsweisenden Technologien auseinandergesetzt.