- Coding & Digital Design FT

- Energy & Sustainability Management FT

- Facility & Real Estate Management PT

- Facility & Real Estate Management FT

- International Business Studies PT

- International Business Studies FT

- Marketing & Communication Management PT

- Marketing & Communication Management FT

- Sports, Culture & Event Management PT

- Sports, Culture & Event Management FT

- Business Management FT

- Industrial Engineering & Management FT

- Curriculum

- Team

- Statements

- Key learning outcomes

- Study insights

- Automation Lab

- Makers Lab

- Specializations

- Bachelor²

- Women in Technology

- Career Paths

- Occupational profiles of graduates

- Graduation requirements

- Examination Regulations, Evaluation and Grading

- Access to further studies

- Podcast Smart Engineering

- Tandem Study Program & Job

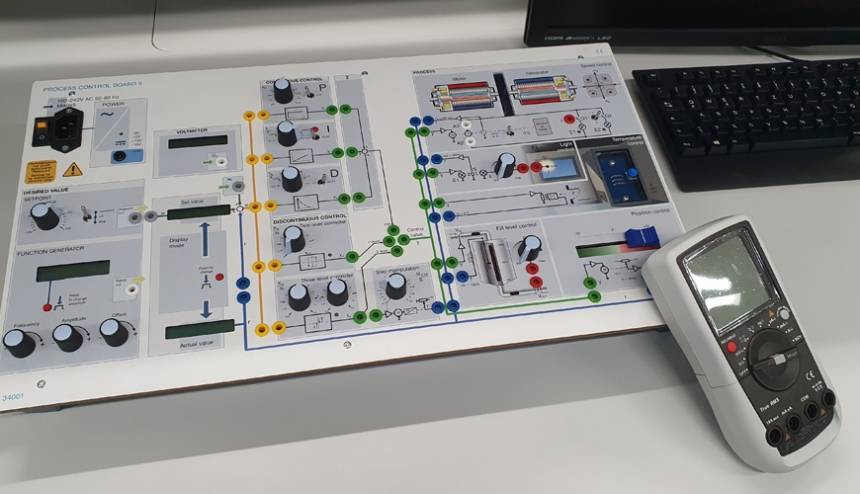

Automation Lab

In the Automation Lab, students have access to a wide range of robots, electronic workstations, measuring equipment, soldering stations and a production line with electro-pneumatic components. This allows them to gain first-hand experience with many of the current issues in automation technology.

To be able to engage with automation processes on a technical level, some foundational knowledge is required. This is why the following topics are taught in the Automation Lab:

- Electrical engineering

- Electronics

- Sensor technology

- Actuator technology

- Data transmission

- Instrumentation and control engineering

Fundamentals

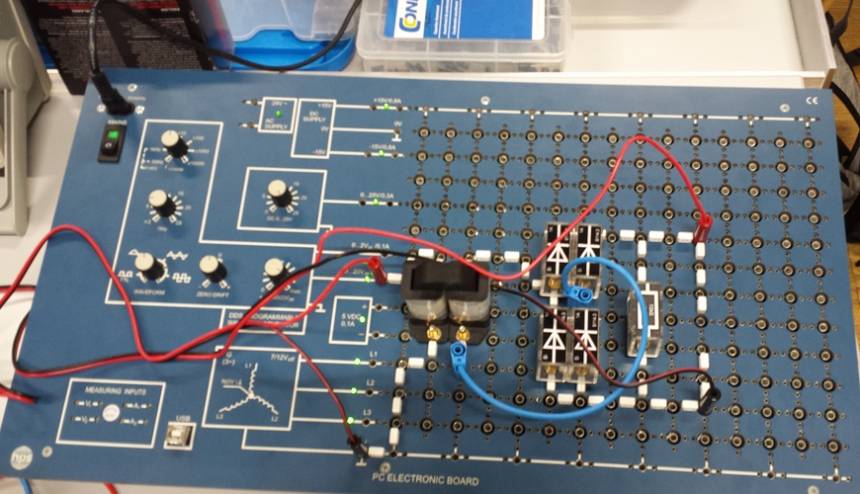

To be able to engage with automation processes on a technical level, some foundational knowledge is required. This is why the topics of electrical engineering, electronics, sensor technology, actuator technology, data transmission, and instrumentation and control engineering are taught in the Automation Lab.

Soldering station with accessories

Control engineering panel

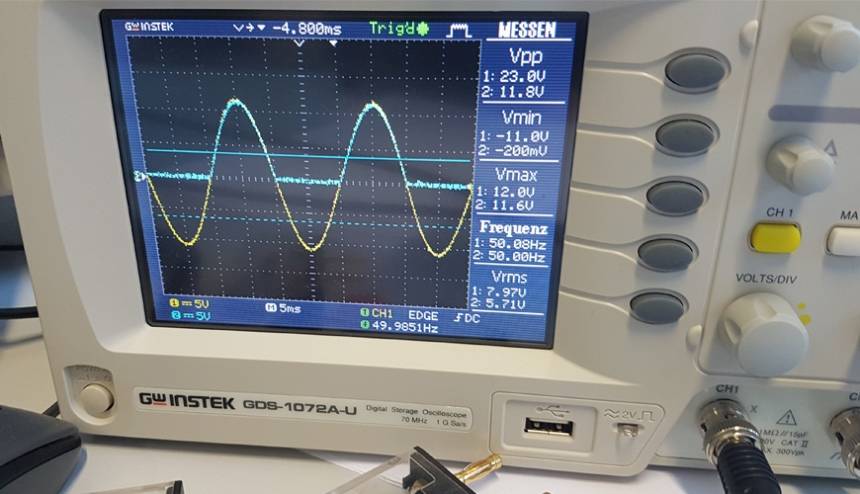

Oscilloscope measuring device

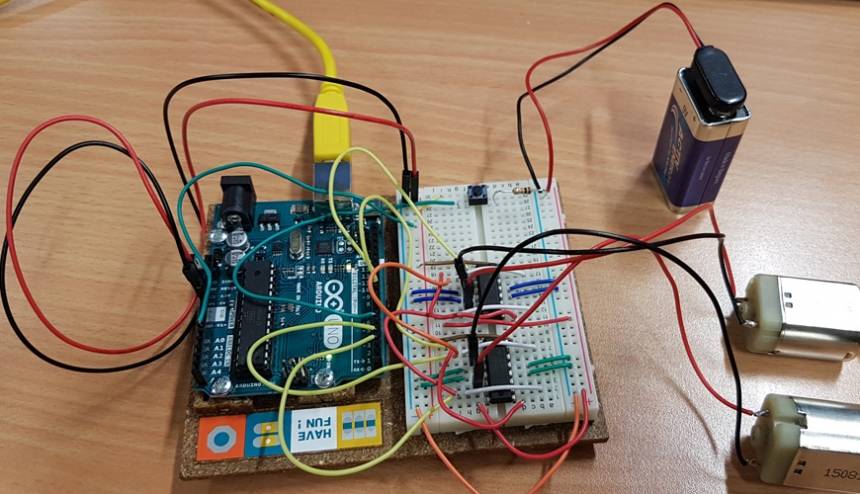

Experimental setup with Arduino, H-bridges and DC motors

Electrical engineering panel with in-situ rectifier circuit

Learning Factory

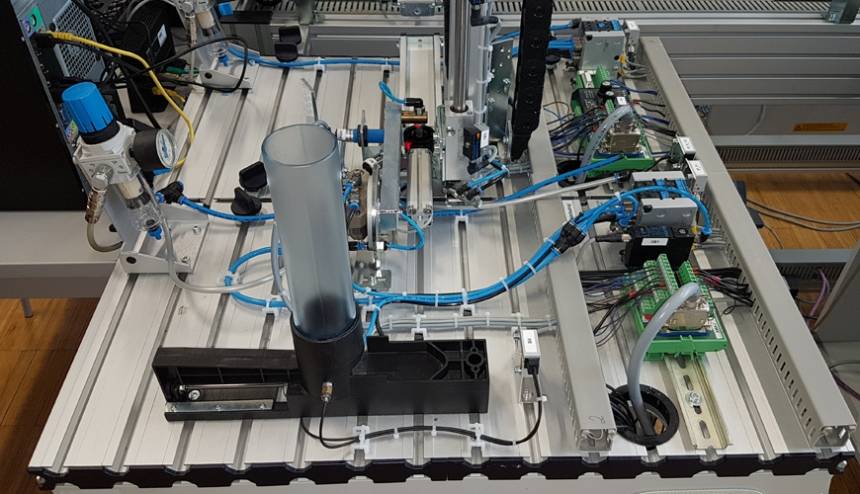

Building on these basics, students in the Automation Lab can take advantage of the many possibilities offered by the Learning Factory of our corporate partner Festo. This is a fully automated industrial production line that connects several workstations with conveyor belts. The setup demonstrates essential steps in the production process – from materials being delivered to the final product being picked for dispatch.

Among other things, students use pneumatics, they program the functioning of workstations, integrate additional machines into the production line, eliminate production bottlenecks, and optimize the energy efficiency of the entire production process.

Festo Learning Factory – Articulated arm robot Mitsubishi

Festo Learning Factory – magazine station

Festo Learning Factory – Control panel with programmable logic controller (PLC)

Robotics

No production line in industry today is conceivable without robots. Robotics is therefore an important part of the content covered in the Industrial Engineering & Management degree program.

The Automation Lab boasts a wide range of robotic systems, from classic 5-axis articulated arm robots to collaborative, mobile robots and humanoid robots. In this lab, students learn about the variety of different robots and their different programming and operating options.

Collaborative robot in a pick-by-light setup

Collaborative robot in a pick-by-light setup

Humanoid robot and lightweight collaborative robot

Mobile Roboter transportieren fertige Produkte der Fertigungsstraße in ein dezentrales Lager

Der humaniode Roboter ist startklar

Digitalization

The digitization of production is well advanced in many companies. In the Automation Lab, we prepare our Industrial Engineering & Management students to be able to help shape this process in their future professional lives. This requires familiarity not just with all the hardware, but also the necessary software products. We regularly work with products from Siemens, such as their TIA Portal or their LOGO! Soft Comfort software package. Combined with the virtualization software CIROS by Festo, this allows students to learn how to make adjustments using a virtual twin of the production line before they are implemented in the physical production line.

Navigation

Contact